South DakotaDepartment of Transportation

Transportation

Aviation

About Office of Aeronautics Services

Office of Aeronautics Services

Airports Conference

Aerospace Education

Airport Information

Links

Aviation Systems Plan

Bridges

Office of Bridge Design

Design & Plans

Historical Bridges

Inventory & Inspection

Posted Structures

Reference Information

SD Bridge Photos

Doing Business

Certification & Accreditation

About Certification & Accreditation

SDDOT Accreditation Certification List

Approved Products

Manuals & Documents

Welding Certifications

Training

Contractors

Bid Letting Information

Concrete Pipe Release

Contractors/Suppliers

Prequalified Contractors

CMS Web Reports

Disadvantaged Business Enterprise (DBE)

Fuel Price Index

Labor Compliance

Materials

Preconstruction Meetings

Price Adjustment Guidelines

Standard Specifications

Subcontract Requirements

Forms & Documents

Webinars

Alternative Contracting

Engineering/Design Services

Consultant Services

Downloadable Files

Manuals

News & Updates

Right of Way / Relocation Assistance

Standard Bid Items

Standard Plates

Surveyors

Utility Coordination

Environmental

About Environmental

Agreements

Endangered Species

Environmental Assessments

Forms

Public Involvement

Stormwater

Wetland Mitigation

Local Governments

About Local Governments

Bridge Improvement Grants

City/County Fund Balances

Emergency Relief (ER)

Federal Bridge Program

Forms & Documents

Secure Accounts Billing

Transportation Economic Development Grants

Urban Systems

Rural Access Infrastructure Fund Program

Traffic Incident Management

Training

Projects & Studies

Planning

Carbon Reduction Strategy

Freight Plan

Long Range Plan

Metropolitan Planning Organization

Non-state Public Road Inventory

Pavement Condition Monitoring

Pavement Management

South Dakota EV Fast Charging Plan

Statewide Transportation Improvement Program – STIP

Transportation Asset Management Plan (TAMP)

Inside SDDOT

Forms & Publications

Brochures

Forms

Manuals

Maps

Newsletters

Reports

SDDOT Engagement Opportunities

Join One of Our Contact Lists

Press Releases

Media Kits

News Stories

Branding and Identity Guidelines

Learn More about the SDDOT Logo

SDDOT Blog

Materials

Materials

Surfacing section

includes analyzing data, developing typical sections based on type and thickness of pavement layers, materials blends and source availability, life cycle cost analysis, and other factors affecting design and construction of pavements.

Pavement rehabilitation design

includes recommendations for the design of asphalt concrete overlays, design of concrete pavement repairs, asphalt mix & binder type, asphalt mix application rates and other requirements for design and construction.

Asphalt concrete mix designs

includes determining the optimal aggregate blend and asphalt binder content for each project based on the materials and specifications to be used.

Portland cement concrete mix designs

Responsibilities include determining the cementious material, fine and coarse aggregate, concrete additives and water combinations necessary to optimize strength, durability and workability of a concrete pavement. Also, determines and reviews special concrete mixes for particular applications and is involved with the testing and acceptance of the pipe, precast, and prestressed items.

Pavement smoothness testing

Includes verification of the smoothness of newly constructed concrete and asphalt roadways.

Coring of pavements

Includes coring of concrete and asphalt pavements to determine thickness of the surfacing materials.

Technical assistance

Includes providing technical assistance relating to materials problems to field personnel and other governmental entities during design and construction.

Bituminous (liquid asphalt) lab

Includes performing acceptance testing of all liquid asphalt used in construction and maintenance statewide.

Asphalt mix design lab

Includes performing and verifying Contractor submitted asphalt mix designs. Mix designs are performed using Marshall Mix and Superpave Mix Designs Methods.

Concrete lab

Includes performing concrete mix designs, testing of concrete admixtures, and testing of concrete pipe.

Cement lab

Includes performing tests on cement, fly ash, curing compounds and reinforcing steel.

Chemistry lab

Includes conducting periodic inspection and acceptance testing at wood treatment & metal pipe plants, evaluation of traffic paints, and performs other special acceptance tests.

Aggregate lab

Includes performing quality tests on all aggregate samples.

Nuclear calibration lab

Includes gage procurement, calibration and repair.

Contact

Certification & Accreditation

About Certification & Accreditation

SDDOT Accreditation Certification List

Approved Products

Manuals & Documents

Welding Certifications

Training

Contractors

Bid Letting Information

Concrete Pipe Release

Contractors/Suppliers

Prequalified Contractors

CMS Web Reports

Disadvantaged Business Enterprise (DBE)

Fuel Price Index

Labor Compliance

Engineering/Design Services

Bulletin Board Requirements

Certified Payrolls - let after 6/5/19

Davis-Bacon Wage Requirements and Defined Work Classifications

Materials

Preconstruction Meetings

Price Adjustment Guidelines

Standard Specifications

Subcontract Requirements

Forms & Documents

Webinars

Alternative Contracting

Consultant Services

Downloadable Files

Manuals

News & Updates

Right of Way / Relocation Assistance

Standard Bid Items

Standard Plates

Surveyors

Utility Coordination

Environmental

About Environmental

Agreements

Endangered Species

Environmental Assessments

Forms

Public Involvement

Stormwater

Wetland Mitigation

Local Governments

About Local Governments

Bridge Improvement Grants

City/County Fund Balances

Emergency Relief (ER)

Federal Bridge Program

Forms & Documents

Secure Accounts Billing

Transportation Economic Development Grants

Urban Systems

Rural Access Infrastructure Fund Program

Traffic Incident Management

© 2026 State of South Dakota. All Rights Reserved.

South Dakota Department of Transportation

Becker-Hansen Building

700 E. Broadway Ave.

Pierre, SD 57501

Becker-Hansen Building

700 E. Broadway Ave.

Pierre, SD 57501

Powered by:

Modern Logic

Modern Logic

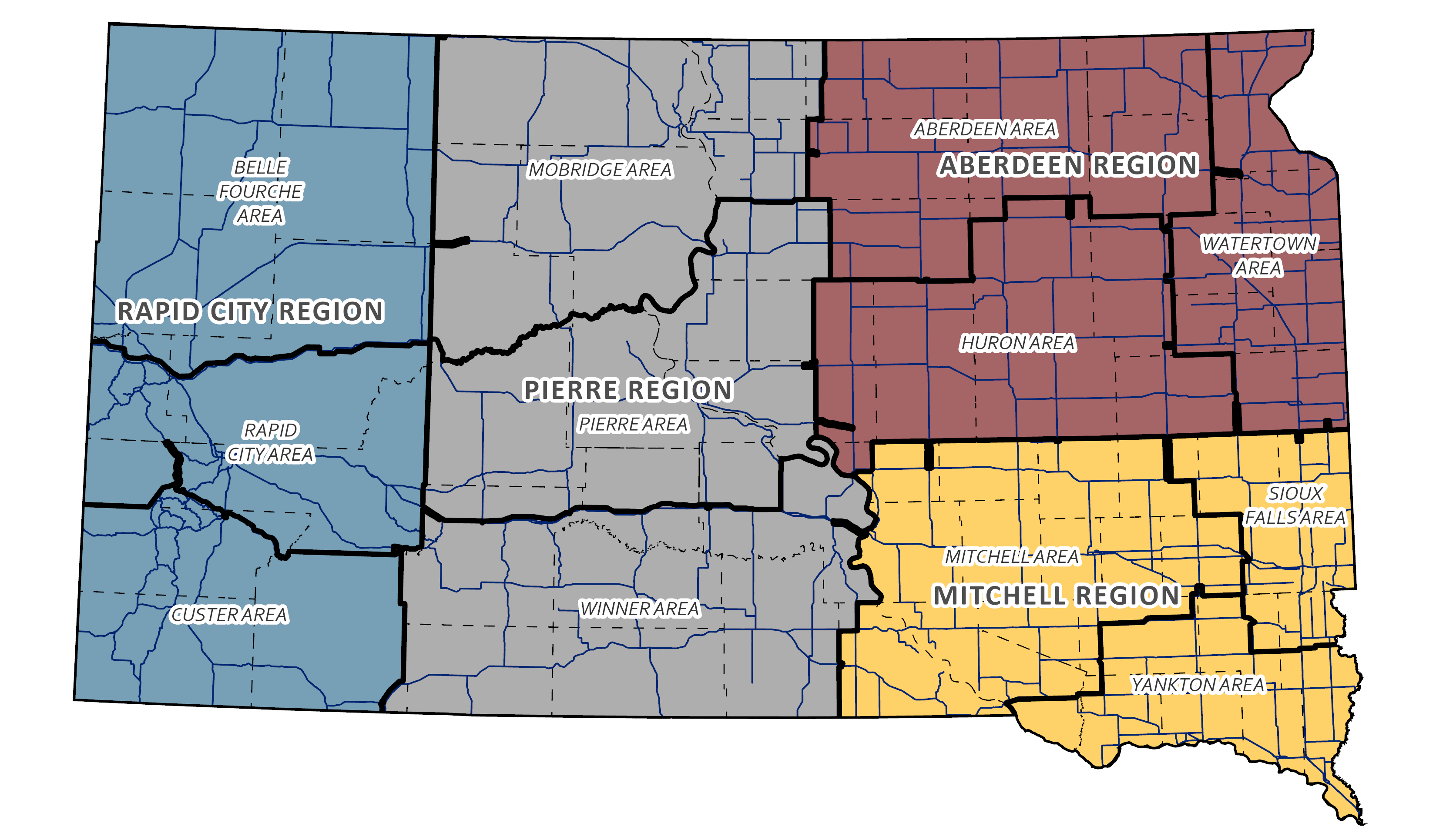

Region & Area Offices

Travelers

© 2026 State of South Dakota. All Rights Reserved.

South Dakota Department of Transportation

Becker-Hansen Building

700 E. Broadway Ave.

Pierre, SD 57501

Becker-Hansen Building

700 E. Broadway Ave.

Pierre, SD 57501

Powered by:

Modern Logic

Modern Logic