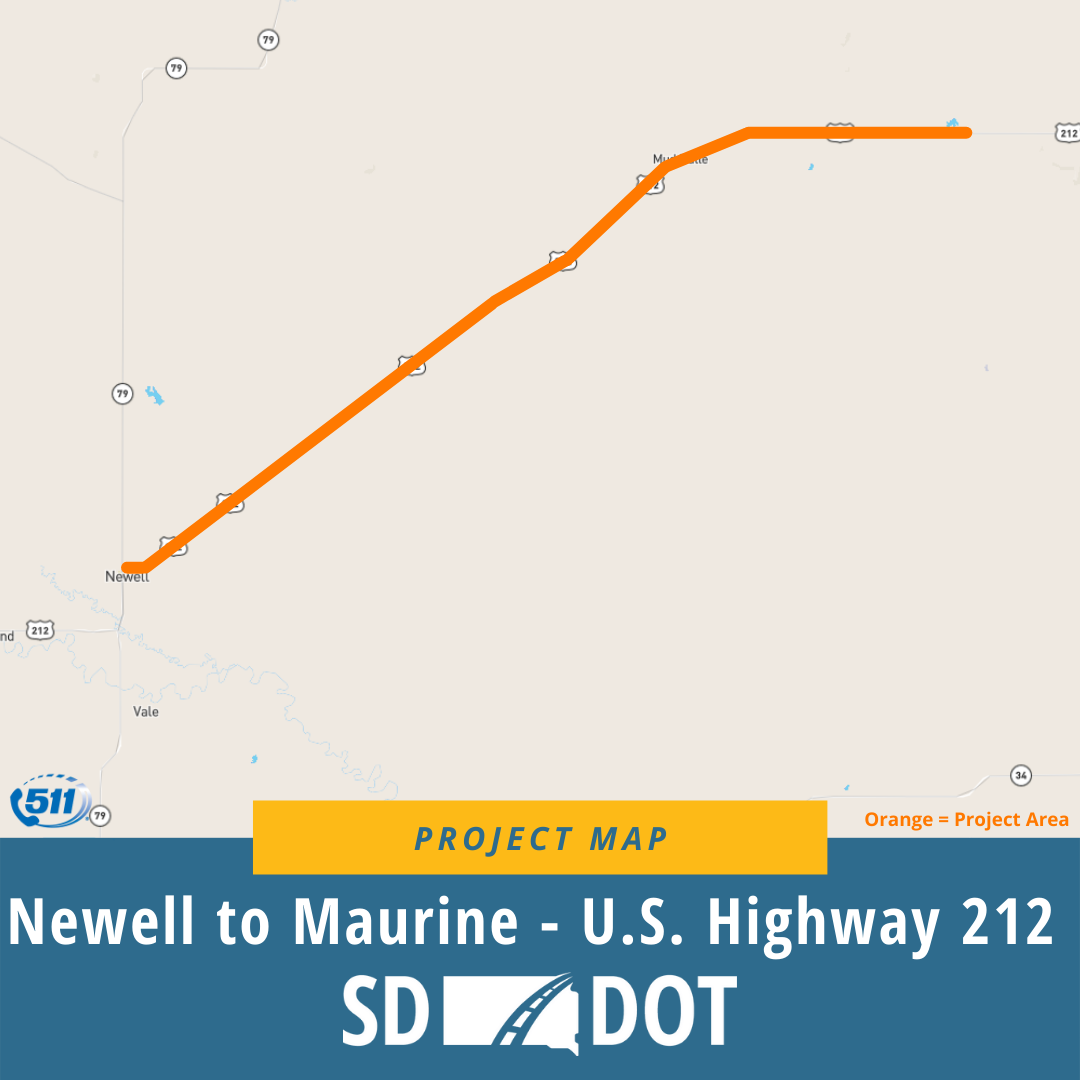

Newell to Maurine - U.S. Highway 212

PROJECT COMPLETE

Project Summary:

The project is on U.S. Highway 212 from Newell to Maurine, about 48 miles. The highlights of this project consist of 96 pipe repair sites, FDR, which is Full Depth Reclamation of the shoulders for certain sections of the roadway, and the placing of 125,000 tons +/- of asphalt concrete pavement.

The benefits include the replacement of aged driving surface for a smoother ride, improved drainage and paved shoulders.

Project Timeline:

Spring 2022 - Summer of 2023

Project Updates:

July 26, 2023:

July Completed Work: The contractor has completed all required work for this project. July work completed includes permanent striping and mailbox replacement.

Anticipated work in August: No work scheduled for August. All work has been completed.

---

June 22, 2023:

June Completed Work: The contractor has completed all the full-depth reclamation shoulders and the asphalt concrete paving. The grinding of the rumble stripes/strips has also been completed. The contractor is currently working on the flush seal operation and should be completed by the end of June.

Anticipated Work in July: Remaining work to be completed in July includes permanent striping and minor clean-up.

---

May 24, 2023:

May Completed Work: 14 miles of Full Depth Reclamation Shoulders have been completed. 17 miles of blade-laid asphalt and seven miles of surface asphalt paving have been completed.

Anticipated Work in June: Complete the Full Depth Reclamation Shoulder work and complete the asphalt paving.

---

April 21, 2023: Milling and Full Depth Reclamation operations will begin on April 24th, with paving to start roughly two weeks afterward

---

April 21, 2023: BELLE FOURCHE, S.D. – Milling and paving operations on U.S. Highway 212 east of Newell will resume on Monday, April 24, 2023. Traffic will be reduced to one lane, with pilot car operations guiding motorists through the work zone. Delays of up to 15 minutes can be expected while traveling through the work area during daytime hours. Read the full release here.

Project Photos:

October 2022:

Coring of new asphalt concrete pavement. Cores are used in testing. The plant site is in the background.

The newly paved section of U.S. Highway 212

Photo 1 is showing the belly dump that transports the hot mix from the plant to the road where it dumps the hot mix in a windrow in front of paver.

Photo 2 is showing the windrow before the paver and nice flat mat behind the paver.

August and September 2022:

(Asphalt Concrete Plant)

From left to right is the white silo which is lime storage that is incorporated into the mix. Next is the cold feed conveyor which brings in the various aggregates into the drum mixer. Behind the cold feed is the drum mixer which dries and mixes the asphalt concrete components. Next is the conveyor that puts the hot mix into a hopper which is weighed and dumped into the haul trucks. You can see the front of the truck being loaded. Next to the truck is the control shack. Next to the control shack is power supply that powers all the electrical needs to the plant.

(Hydro Seeding)

From L to R: Hydro seeding equipment - the area being seeded (various pipe repair process areas) - finished product.

July 2022:

(L to R: Joint Repair and Void Fill of an 84” Pipe, A Cattle Pass before the Joint Repair and Void Fill Work, Gabion Basket at Pipe Outlet for Erosion Prevention)

----

Photos P1-P8 shows CIPP (Cured-In-Place Pie). This method of pipe repair treatment is competitive cost-wise with other pipe repair treatments, reduces traffic delays and is quicker to complete.

The contractor:

- Jets the pipe. (cleans pipe with high pressure equipment)

- Pulls a plastic sleeve through the pipe to help facilitate pulling the liner through the pipe

- Pulls liner through the pipe (orange plastic bag looking material)

- Attaches the cans to the liner on both pipe ends (the cans are the disc looking items)

- Lightly inflates the liner

- Slides the light sled into liner

- Inflates liner to full pressure

- Pulls light sled, camera and other measuring instruments through the liner

- Activates light sled at a controlled rate to cure liner

- Removes cans

- Peals plastic coat off liner

- Trims liner to fit pipe end

- PRESTO! The pipe is lined and ready for use

P1: Liner is cut to length at a fabrication shop and spooled. Photo shows unspooling liner into pipe.

P2: Liner is in place. The can is to the right which will be attached to liner.

P3: Placing liner in can which helps pressurize liner.

P4: Pipe end 1 which shows cable coming out of can pulls light sled through the liner.

P5: Pipe end 2 which shows large air tube to pressurize liner and cable energizes equipment.

P6: Photo of final product.

P7: Support Truck 1 which pressurizes liner and supplies power to equipment.

P8: Support Truck 2 which performs other functions such as camera operations. There are other vehicles not shown such as the jetter truck used to clean pipe.

____

Compaction for full-width pipe replacement

Bore and Jack operation angle 1